1. Natural Bleaching: Traditional cotton production often uses harsh chemicals like chlorine for bleaching, which can be harmful to both the fibres and the environment. At Tervcot, we have chosen alternative, eco-friendly bleaching methods. We use mild oxygen-based bleaches that do not destroy the fibres or leave any traces of chemicals on them. This helps preserve the natural shade of the cotton, its softness and hypoallergenic properties.

2. Using Natural Softeners: To soften the cotton fibre, we use natural and biodegradable softeners that make the cotton soft and pleasant to the touch without subjecting it to harsh chemical treatments. This keeps the fibres intact and protects their natural qualities. Natural softeners make our cotton suitable even for delicate and sensitive skin.

3. Use of Eco-Friendly Dyes: On our farm, we offer cotton that is easy to dye with natural and eco-friendly dyes. This means that our fabrics can be dyed without the need for synthetic and toxic dyes, making the dyeing process safe for consumers and environmentally friendly.

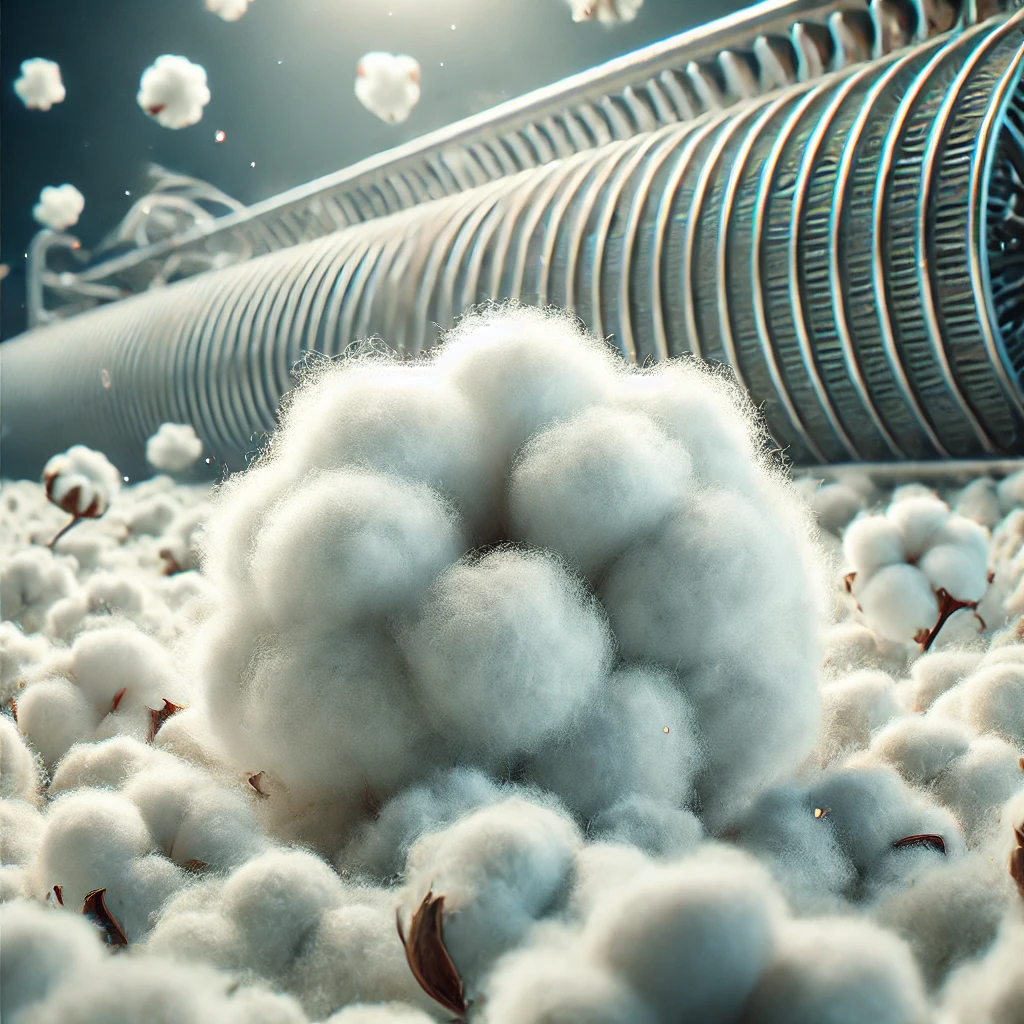

4. Gentle Fiber Treatment: When processing cotton fibers, we avoid the use of aggressive chemical reagents that can change the structure of the fiber. We use mechanical and water cleaning methods that minimize the impact on the fiber, preserving its structure and texture. Such treatment also reduces the risk of allergens, which is especially important for creating hypoallergenic products.

5. Safe Fiber Disinfection: At the disinfection stage, we use steam and UV-based methods instead of traditional chemical disinfection. This allows us to effectively remove microorganisms and prevent the appearance of fungi and mold without the use of toxic substances. Disinfection using steam and UV radiation is a safe way to make our cotton clean and ready for production.